With Technology for Operational Efficiency at the forefront, this paragraph opens a window to an amazing start and intrigue, inviting readers to embark on a storytelling journey filled with unexpected twists and insights. Operational efficiency is a crucial aspect of modern businesses, and leveraging technology is key to achieving success in this area. Let’s delve into how technology transforms and optimizes operations across various industries.

Technology for Operational Efficiency

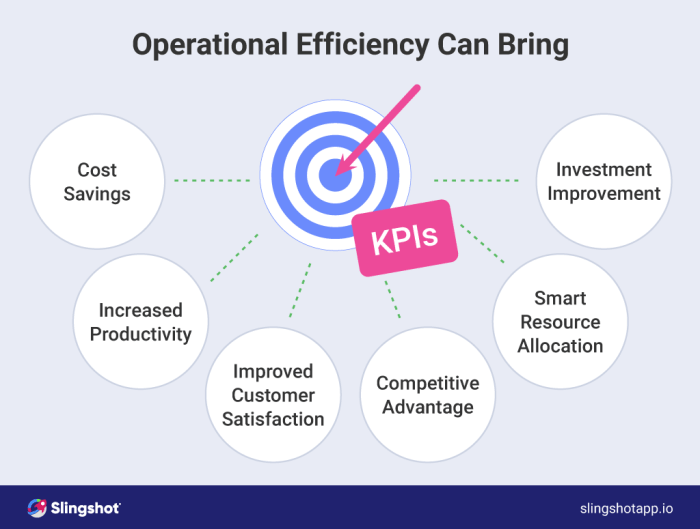

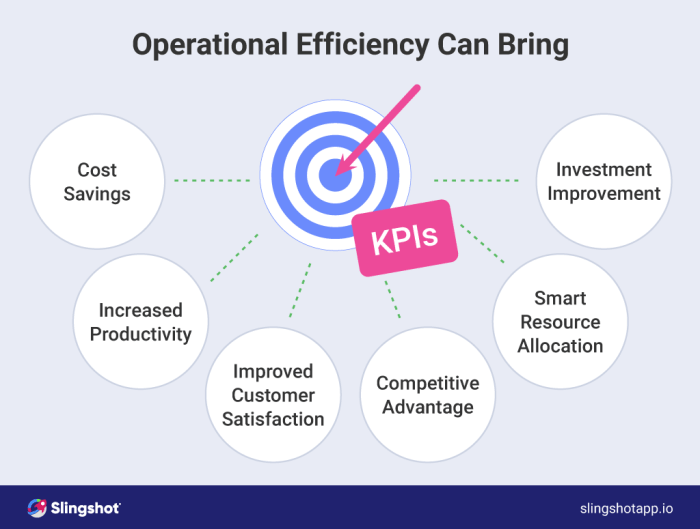

Operational efficiency in business operations refers to the ability to maximize output while minimizing input, thus achieving optimal productivity and cost-effectiveness.

Role of Technology in Enhancing Operational Efficiency

Technology plays a crucial role in enhancing operational efficiency by automating tasks, streamlining processes, and providing real-time data insights for informed decision-making.

Key Technologies for Improving Operational Efficiency

- Internet of Things (IoT): IoT devices enable the collection of data from various sources, allowing businesses to monitor operations remotely and optimize resource usage.

- Artificial Intelligence (AI): AI algorithms can analyze vast amounts of data quickly, identify patterns, and suggest improvements to streamline operations.

- Cloud Computing: Cloud-based solutions provide scalability, flexibility, and accessibility, allowing businesses to store and access data securely from anywhere.

- Robotic Process Automation (RPA): RPA automates repetitive tasks, reducing errors and freeing up human resources to focus on higher-value activities.

Examples of Technology Transforming Operational Processes

- In the manufacturing industry, the adoption of IoT sensors has revolutionized supply chain management by enabling real-time tracking of inventory and predictive maintenance of equipment.

- Retail businesses utilize AI-powered analytics to analyze customer behavior, optimize inventory management, and personalize marketing strategies for improved sales performance.

- Healthcare providers leverage cloud computing to securely store and share patient data, facilitate telemedicine consultations, and enhance collaboration among healthcare professionals.

- Financial institutions implement RPA to automate back-office processes like data entry, account reconciliation, and compliance checks, improving operational efficiency and reducing operational costs.

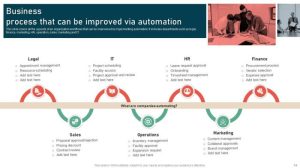

Automation for Streamlining Operations

Automation plays a crucial role in enhancing operational efficiency by reducing manual intervention and streamlining processes. By leveraging automation tools and software, businesses can optimize their operations and achieve higher levels of productivity.

Examples of Repetitive Tasks for Automation

- Automated data entry and data migration processes

- Automated report generation and distribution

- Automated email responses and customer notifications

- Automated inventory management and restocking

Benefits of Implementing Automation

- Improved accuracy and reduced errors in tasks

- Enhanced productivity through faster task completion

- Cost savings by reducing manual labor and human error

- Increased scalability and flexibility in operations

Automation for Error Reduction and Productivity Enhancement

Automation significantly reduces errors in operations by eliminating manual data entry mistakes and ensuring consistency in processes. This leads to enhanced productivity as employees can focus on more strategic tasks rather than repetitive manual work.

Data Analytics for Decision-Making

Data analytics tools play a crucial role in helping businesses make data-driven decisions to enhance operational efficiency. By analyzing large sets of data, organizations can gain valuable insights that can lead to informed decision-making processes.

Real-Time Analytics for Operational Optimization

Real-time analytics is essential for optimizing operational processes as it allows businesses to monitor and analyze data as it is generated. This enables companies to identify issues promptly, make quick adjustments, and improve overall operational performance in a timely manner.

- Real-time monitoring of production lines to detect and address inefficiencies immediately.

- Dynamic pricing strategies based on real-time market data to maximize profitability.

- Real-time inventory management to prevent stockouts and overstock situations.

Predictive Analytics for Forecasting Operational Needs

Predictive analytics plays a vital role in forecasting operational needs and trends by analyzing historical data to predict future outcomes. By leveraging predictive models, businesses can anticipate demand, optimize resource allocation, and make proactive decisions to stay ahead of the competition.

- Forecasting customer demand to adjust production schedules and inventory levels accordingly.

- Predictive maintenance to prevent equipment failures and minimize downtime.

- Optimizing supply chain logistics by predicting shipping delays and rerouting shipments in advance.

Integration of IoT in Operational Processes

IoT devices play a crucial role in streamlining operational processes by enabling seamless communication and data exchange between various systems and devices. This integration enhances efficiency and productivity in a wide range of industries.

Benefits of IoT sensors in monitoring and optimizing operational workflows

- Real-time Monitoring: IoT sensors provide real-time data on equipment performance, allowing for proactive maintenance and minimizing downtime.

- Improved Efficiency: By collecting and analyzing data, IoT sensors help identify bottlenecks in operations and optimize workflow processes for increased efficiency.

- Cost Savings: With IoT sensors, businesses can reduce energy consumption, improve resource allocation, and minimize waste, leading to significant cost savings.

- Enhanced Safety: IoT sensors can monitor environmental conditions and ensure compliance with safety regulations, creating a safer work environment for employees.

Examples of industries leveraging IoT for operational efficiency

- Manufacturing: IoT devices are used to track inventory, monitor equipment performance, and optimize production processes in manufacturing plants.

- Logistics and Supply Chain: IoT sensors enable real-time tracking of shipments, inventory management, and route optimization for efficient logistics operations.

- Healthcare: IoT devices help in remote patient monitoring, inventory management of medical supplies, and asset tracking for improved healthcare services.

How IoT data is used to enhance decision-making and efficiency in operations

- Data Analytics: IoT data is analyzed to gain insights into operations, identify patterns, and make informed decisions for process optimization.

- Predictive Maintenance: By analyzing IoT data, businesses can predict equipment failures before they occur, enabling preventive maintenance and minimizing downtime.

- Performance Optimization: IoT data helps in identifying inefficiencies in operations, enabling businesses to streamline processes and improve overall performance.

In conclusion, Technology for Operational Efficiency plays a vital role in revolutionizing business processes, driving growth, and ensuring competitiveness in today’s dynamic market landscape. By embracing the right technologies and strategies, organizations can streamline operations, make data-driven decisions, and harness the power of automation to unlock new levels of efficiency and productivity.

Questions Often Asked

How does technology impact operational efficiency?

Technology enhances operational efficiency by automating tasks, providing real-time data insights, and streamlining processes.

What are some common technologies used to improve operational efficiency?

Common technologies include automation tools, data analytics software, and IoT devices that help optimize workflows.

Why is data analytics important for operational decision-making?

Data analytics provides valuable insights into operational performance, trends, and areas for improvement, enabling informed decision-making.