Measuring Operational Efficiency sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail with a casual formal language style and brimming with originality from the outset.

Understanding the importance of operational efficiency in business operations and its impact on the bottom line is crucial for sustained success.

What is Operational Efficiency?

Operational efficiency refers to the ability of a business to deliver products or services to customers in the most cost-effective manner possible while maintaining high quality standards. It involves optimizing processes, eliminating waste, and maximizing resources to achieve the best possible outcomes.

Operational efficiency is crucial for businesses as it directly impacts their profitability, competitiveness, and overall success in the market. By streamlining operations and reducing inefficiencies, companies can lower costs, improve productivity, and enhance customer satisfaction.

Importance of Operational Efficiency

Efficient operations can significantly impact a company’s bottom line in various ways:

- Cost Reduction: By identifying and eliminating unnecessary expenses, businesses can lower their production costs and increase profit margins.

- Improved Productivity: Streamlining processes and workflows can boost employee efficiency, leading to higher output levels and faster delivery times.

- Enhanced Quality: Operational efficiency can help maintain consistent quality standards, reducing errors and defects in products or services.

- Increased Customer Satisfaction: Efficient operations enable companies to meet customer demands promptly and effectively, enhancing overall satisfaction and loyalty.

Key Metrics for Measuring Operational Efficiency

Operational efficiency is crucial for the success of any organization, and measuring it accurately requires the use of specific key metrics. These metrics provide valuable insights into how well operational processes are performing and help in identifying areas for improvement.

1. Overall Equipment Effectiveness (OEE)

- OEE is a comprehensive metric that combines availability, performance, and quality to measure the overall efficiency of equipment.

- It helps in assessing how well equipment is utilized, the speed at which it operates, and the quality of output it produces.

- By calculating OEE, organizations can pinpoint bottlenecks, downtime issues, and quality defects that impact operational efficiency.

2. Cycle Time

- Cycle time measures the total time it takes to complete a specific task or process, from start to finish.

- It is a critical metric for determining the efficiency of production lines and workflows.

- Monitoring cycle time helps in identifying delays, inefficiencies, and areas where improvements can be made to streamline operations.

3. Inventory Turnover Ratio

- The inventory turnover ratio indicates how many times a company’s inventory is sold and replaced over a specific period.

- A high turnover ratio suggests efficient inventory management and quick sales, while a low ratio may indicate overstocking or slow-moving inventory.

- By analyzing this metric, organizations can optimize inventory levels, reduce carrying costs, and improve cash flow.

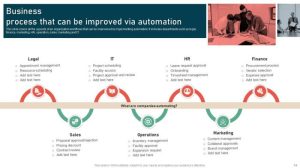

Strategies to Improve Operational Efficiency

Improving operational efficiency is crucial for businesses to optimize their processes and resources effectively. By implementing the right strategies, organizations can streamline operations, reduce costs, and enhance overall performance.

Implement Lean Methodologies

One effective strategy to improve operational efficiency is by implementing lean methodologies. This approach focuses on eliminating waste, optimizing processes, and improving productivity. By identifying and eliminating non-value-added activities, businesses can streamline their operations and enhance efficiency. For example, Toyota successfully implemented lean principles in their manufacturing processes, leading to significant improvements in productivity and cost savings.

Utilize Technology Solutions

Technology plays a crucial role in optimizing operational efficiency. Businesses can leverage automation, data analytics, and other technological solutions to streamline processes, reduce manual tasks, and improve decision-making. For instance, companies can implement enterprise resource planning (ERP) systems to integrate and streamline various functions, leading to improved efficiency and productivity.

Empower Employees

Empowering employees and fostering a culture of continuous improvement can also enhance operational efficiency. By encouraging employee involvement, providing training opportunities, and recognizing their contributions, businesses can boost morale, increase productivity, and drive innovation. For example, companies like Google and Amazon prioritize employee development and engagement, leading to higher efficiency and performance across their operations.

Challenges in Measuring Operational Efficiency

Organizations often face various challenges when trying to measure operational efficiency. These challenges can impact decision-making processes and overall performance if not addressed effectively. It is crucial to identify these obstacles and find solutions to improve the measurement process.

Lack of Standardized Metrics

One common challenge is the lack of standardized metrics for measuring operational efficiency across different departments or industries. This can lead to inconsistencies in data collection and analysis, making it difficult to compare performance accurately.

Poor Data Quality

Another challenge organizations face is poor data quality, which can result in inaccurate measurements of operational efficiency. Incomplete, outdated, or incorrect data can skew results and provide a misleading picture of performance.

Complexity of Operations

The complexity of operations within an organization can also pose challenges in measuring operational efficiency. With multiple interconnected processes and systems, it can be challenging to isolate specific factors affecting efficiency and accurately measure their impact.

Resistance to Change

Resistance to change within an organization can hinder efforts to improve operational efficiency measurement. Employees may be reluctant to adopt new tools or methodologies, making it difficult to implement changes effectively.

Technological Limitations

Technological limitations, such as outdated systems or incompatible software, can also impede the measurement of operational efficiency. Without the right tools and technologies in place, organizations may struggle to collect and analyze data efficiently.

In conclusion, Measuring Operational Efficiency is a vital component for organizations looking to streamline processes, cut costs, and improve overall performance. By implementing the right strategies and overcoming challenges effectively, businesses can achieve greater operational excellence.

FAQ Summary

What are some common challenges faced in measuring operational efficiency?

Common challenges include data accuracy issues, lack of standardized metrics, and resistance to change within organizations.

How can technology help in optimizing operational efficiency?

Technology can automate processes, provide real-time data insights, and streamline workflows to enhance operational efficiency.