Kicking off with Cost Reduction through Operational Efficiency, this opening paragraph is designed to captivate and engage the readers, providing an intriguing glimpse into how businesses can streamline operations to save costs effectively.

Exploring the significance of operational efficiency and how it directly correlates to reducing expenses, this introduction sets the stage for a comprehensive discussion on optimizing business processes for financial gains.

Cost Reduction through Operational Efficiency

Operational efficiency in a business context refers to the ability of an organization to maximize output while minimizing input. This involves streamlining processes, eliminating waste, and optimizing resources to achieve the desired results in the most effective and efficient manner.Cost reduction is crucial for a company as it directly impacts profitability and competitiveness in the market. By lowering expenses, a company can improve its bottom line, reinvest in growth opportunities, and potentially lower prices for customers, gaining a competitive edge.

Importance of Operational Efficiency in Cost Reduction

Operational efficiency plays a key role in reducing costs for a company. By optimizing workflows and eliminating inefficiencies, businesses can achieve significant savings in various areas:

- Reduced Labor Costs: Implementing efficient processes can help businesses accomplish more with fewer resources, reducing labor expenses.

- Lower Inventory Costs: Streamlining inventory management can minimize excess stock, storage costs, and the risk of obsolescence.

- Decreased Overhead Expenses: By optimizing resource utilization and eliminating unnecessary expenses, companies can lower overhead costs.

Strategies for Achieving Operational Efficiency

Achieving operational efficiency is crucial for businesses looking to reduce costs and improve overall performance. By implementing the right strategies, companies can streamline their processes, optimize resources, and enhance productivity. Let’s explore some effective strategies that companies can use to achieve operational efficiency.

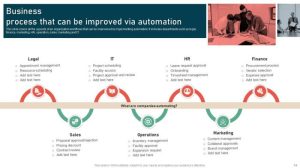

Automation of Routine Tasks

One of the key strategies for achieving operational efficiency is the automation of routine tasks. By automating repetitive and time-consuming processes, companies can reduce errors, improve speed, and free up employees to focus on more strategic tasks. For example, companies like Amazon have successfully implemented automation in their warehouses to streamline order fulfillment processes.

Optimizing Supply Chain Management

Efficient supply chain management is essential for reducing costs and improving operational efficiency. Companies can optimize their supply chains by consolidating suppliers, implementing just-in-time inventory systems, and leveraging technology for real-time tracking. For instance, companies like Walmart have effectively optimized their supply chains to minimize inventory holding costs and improve delivery times.

Employee Training and Development

Investing in employee training and development is another important strategy for achieving operational efficiency. Well-trained employees are more productive, engaged, and capable of making informed decisions. Companies like Google are known for their extensive employee training programs, which help employees develop new skills and stay updated on the latest industry trends.

Key Factors Influencing Operational Efficiency

Operational efficiency within an organization can be influenced by several key factors that play a crucial role in optimizing processes and reducing costs.

Technology Optimization

Technology plays a vital role in optimizing operational processes for cost reduction. Implementing advanced software solutions, automation tools, and data analytics can streamline operations, improve accuracy, and enhance productivity. By leveraging technology effectively, organizations can eliminate manual tasks, reduce errors, and achieve greater efficiency in their day-to-day operations.

Continuous Improvement

Continuous improvement is essential for maintaining operational efficiency. By regularly evaluating processes, identifying bottlenecks, and implementing enhancements, organizations can adapt to changing market conditions and customer demands. Through a culture of continuous improvement, teams can work collaboratively to enhance workflows, eliminate waste, and optimize resource utilization for sustained operational excellence.

Measuring Operational Efficiency

Measuring operational efficiency is essential for businesses to identify areas for improvement and optimize their processes. By using various metrics and key performance indicators (KPIs), organizations can track their performance and make data-driven decisions to enhance efficiency.

Metrics and KPIs for Measuring Operational Efficiency

- 1. Overall Equipment Effectiveness (OEE): OEE measures the performance of equipment in production processes, taking into account availability, performance, and quality.

- 2. Cycle Time: Cycle time measures the time taken to complete a specific task or process, helping to identify bottlenecks and streamline operations.

- 3. Cost per Unit: This metric calculates the cost incurred to produce a single unit of a product or service, indicating the efficiency of production processes.

Data Analysis for Identifying Improvement Areas

Data analysis plays a crucial role in identifying areas for improvement in operational efficiency. By analyzing data collected from various processes, businesses can pinpoint inefficiencies, optimize workflows, and reduce waste. For example, analyzing production data can reveal trends in downtime or defects, leading to targeted improvements in those areas.

Role of Benchmarking in Evaluating Operational Efficiency

Benchmarking involves comparing the performance of a business against industry standards or best practices to evaluate operational efficiency. By benchmarking key metrics such as productivity, cost per unit, or cycle time, organizations can identify gaps in performance and implement strategies to improve efficiency. Benchmarking provides valuable insights into areas where a business is lagging behind competitors and helps set realistic improvement goals.

In conclusion, Cost Reduction through Operational Efficiency is a crucial aspect for any company looking to enhance profitability and sustainability by maximizing operational effectiveness. Dive deeper into the realm of cost-saving strategies and operational excellence to propel your business towards success.

Question & Answer Hub

How can operational efficiency benefit a company?

Operational efficiency can lead to cost savings, improved productivity, and overall streamlined processes, ultimately enhancing the company’s profitability.

What are some common strategies for achieving operational efficiency?

Strategies include process optimization, automation, employee training, and technology integration to streamline operations and reduce costs.

How important is continuous improvement in maintaining operational efficiency?

Continuous improvement is vital as it ensures that operations are consistently optimized, leading to sustained cost reductions and enhanced performance.